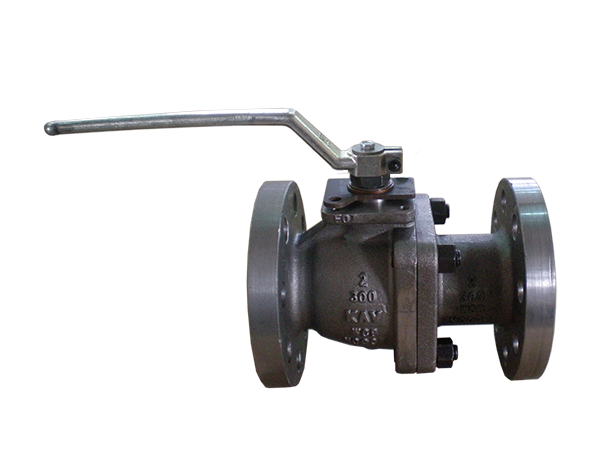

FLOATING BALL VALVES

Kaval Floating Ball valves are straight-through flow valves that provide positive shutoff with minimal pressure drop and turbulence. The barrier to the flow is a ball rotating at 90 degrees in the direction of the flow.

Kaval provides a complete line of ball valves for the most demanding application requirements of the oil and gas, chemical, petrochemical, power and other industries.

KEY FLOATING BALL VALVE FEATURES

- API608 standard and applicable international specifications as required.

- Full port or reduced port design.

- RF, RTJ, NPT, SW or BW end connections.

- Soft seat or metal seat design.

- Fire-safe tested.

- Blow-out proof stem.

- Anti-static Electricity.

- Locking Device.

- Low operating torque for ease of operation and reduced actuator cost.

- Automatic cavity pressure relief.

- Positive Flow Stem Indicator.

- ISO 5211 mounting pad.

- Extended stem for Cryogenic service.

- Non-standard valves designed according to customer specifications.

FLOATING BALL VALVES MADE OF BEST QUALITY MATERIALS

- Carbon Steel

- Stainless Steel

- High-temperature alloy steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

Construction:

Side Entry (2pc/3pcs Bolted, 3pcs thread, fully weld) / Top Entry

Operation:

Manual / Electric / Pneumatic / Hydraulic

FLOATING BALL VALVES SIZE & PRODUCT RATINGS

Size: | Rating: |

|---|---|

1/2" to 10" | 150lb,300lb |

1/2" to 4" | 600lb |

1/2" to 4" | 900lb |

1/2" to 2" | 1500lb,2500lb |